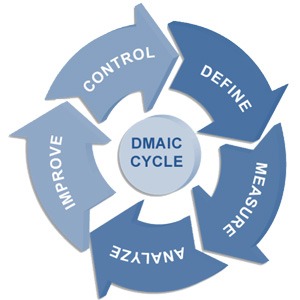

A DMAIC cycle is one of the characteristics of a Lean Six Sigma project. DMAIC is short for Define, Measure, Analyse, Improve, Control. Lean Six Sigma has a structured and systematic approach for organisations to use to solve problems in processes, based on the PDCA approach devised by Deming. In this article, we take a closer look at the how’s and why’s of this DMAIC cycle.

Why DMAIC?

The Lean Six Sigma toolbox contains a selection of tried-and-tested instruments and methods that – if correctly applied – will assist in identifying, investigating and improving process problems. It is important to use the right combination of tools from the Six Sigma toolbox, instead of simply applying all the tools one after the other. Every phase of the DMAIC cycle has associated tools and every phase makes its own contribution to the final result.

Y = f (X)

During Lean Six Sigma projects, it is important to always keep the Y = f (X) concept in mind. This will ensure that you always know what the result of a particular phase should be. Then, it becomes easy to determine what tools from the toolbox are most suitable at that moment in time.

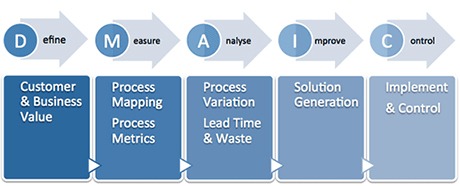

The mathematical formula Y = f (X), interpreted as “Y as a function of x”, illustrates the concept that process results (Y’s) are the result of variables (x’s) within activities. There are numerous examples of x’s: order size, order complexity or the month of the year can all influence Y (on-time delivery in this example). The goal of DMAIC is to determine which set of process variables has the greatest effect on these process outcomes and should therefore be improved. Every DMAIC phase can also be described on the basis of how it contributes to this goal:

- Define: Describe the Y (goal) and the problem experienced.

- Measure: Determine the potential x’s and measure the process performance (x’s and Y).

- Analysis: Test x to Y ratios and determine the most influential x’s.

- Improve: Implement solutions in order to improve the Y. Here, you should focus on the most influential x’s.

- Control: Monitor the most significant x’s and the Y. Determine whether performance has improved and the problem has been solved.

Tollgate review

The DMAIC structure ensures that every phase is carefully completed and that the right tools are applied to the right phase. A tollgate review takes place after every phase, during which the project manager (Black Belt or Green Belt) and the authority (Champion) discuss the results yielded by the phase. What tools were used? Why were these tools chosen? And what contribution has the phase made towards achieving the project objectives? If the result is adequate, the authority gives the project group permission to proceed to the next phase at the end of the tollgate. He can also decide to terminate the project prematurely if the application of Lean Six Sigma tools demonstrates that there is insufficient potential for improvement in the process. The role of the authority is very important here. He must have enough knowledge about Lean Six Sigma and its most important tools to be able to ask the project manager the right critical questions. For this purpose, the authority can participate in so-called champion training.

Conclusion

The DMAIC cycle is an important resource that encourages the structured progress of Lean Six Sigma projects. It ensures focus by forcing one to only consider the x’s that have a major effect on the Y. It is also an important driving factor for the authority, who gets a better grip on the improvement process by means of tollgates.